Varda Space Industries successfully manufactured a sample of HIV medication on board its spacecraft and returned it safely to Earth.

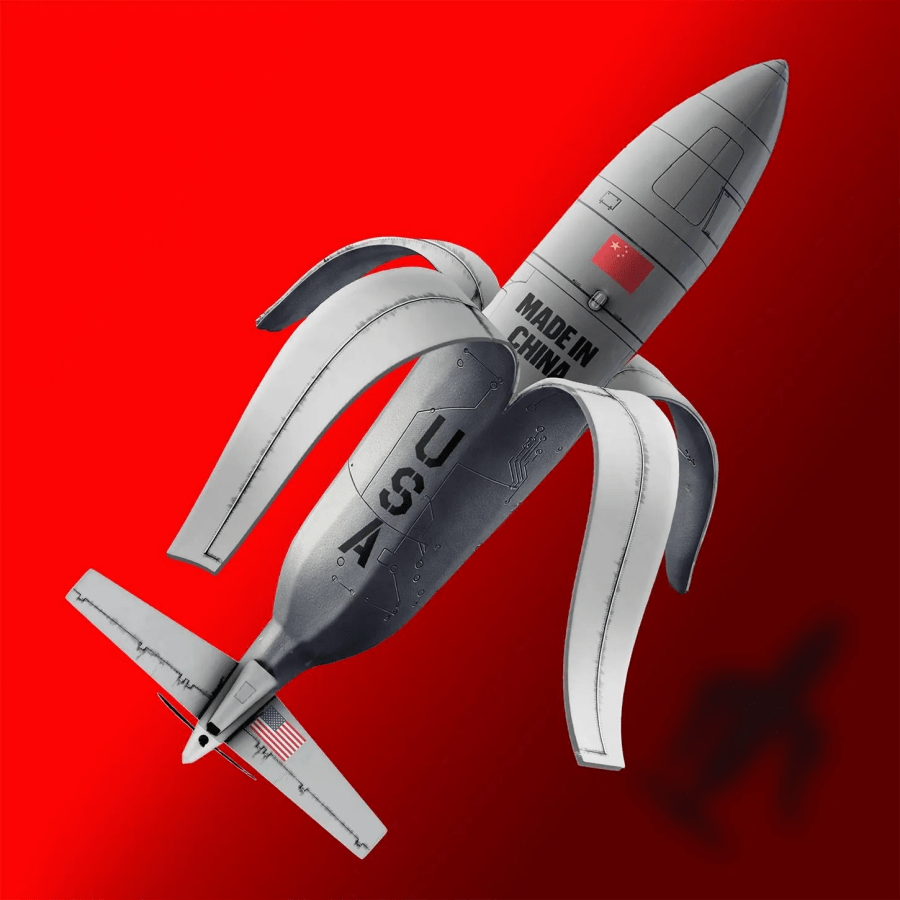

Artist rendering of a Varda spacecraft in orbit

Varda Space Industries

On June 12, 2023, a SpaceX Falcon 9 rocket successfully lifted multiple satellites to orbit, among them the W-1 belonging to California-based Varda Space Industries. On board was a small, automated laboratory and over the course of the eight-month mission, it successfully made a specific form of ritonavir, a drug commonly used to treat HIV. That might not sound like a big deal, but it’s a crucial proof of concept for a technique that paves the way for manufacturing drugs in orbit that can’t be made on Earth.

That Varda’s ritonavir was created exactly as predicted, and remained stable through its return to Earth, is particularly promising. The version of the drug the company attempted is one of its least stable forms. Pulling off its manufacture in space is proof that not only can the company’s technology make a drug in orbit, it can also deliver it safely back to Earth. “Our analysis confirms that we have the same [manufacturing] control in space as we do on Earth,” Varda chief science officer Adrian Radocea told Forbes.

But why would anyone want to manufacture drugs in space? They’re expensive enough already, and rockets aren’t cheap. The answer lies in the process of crystallization. In many drugs, the way that crystallization occurs can have major impacts on manufacturing costs, overall quality, stability and how well it works on patients. Plus, it can determine whether it can be made as a pill or will require an IV.

And as it turns out, in the microgravity of space, it’s easier to make certain crystals than it is here on Earth, and to have finer control over the process. That’s why experiments with protein crystallization have been ongoing on the International Space Station for over two decades now. In the past year, pharmaceutical giants Bristol Myers Squibb and Lilly have both established protein crystallization experiments to the International Space Station.

One key breakthrough, said Varda cofounder and president Delian Asparouhov, is a 2019 experiment performed on the International Space Station with Merck’s cancer drug Keytruda. That research found that in microgravity, it was possible to make stable crystal forms of the drug that could be delivered with an injection and stored at room temperature. That’s a huge difference — the Earth-made version requires refrigeration and can only be administered to patients via IV.

The W-1, which crystalized samples of ritonavir in space, being recovered after a safe landing.

John Kraus/Varda Space Industries

That experiment was impressive, Asparouhov said, but also showed the limitations of using the ISS as the primary place to do this kind of research. “The cadence has been way too low and the costs have been way too high,” he said. That’s because the ISS is a complex spacecraft certified to safely carry people, “but humans are not really necessary” to make drug ingredients without needing any astronauts on board.

That’s what ultimately led to the founding of Varda in 2020 by Asparouhov, Will Bruey and Daniel Marshall. (Marshall left the company in 2022.) The company has since raised $54 million in venture capital to date, at a valuation of $149.5 million, according to Pitchbook. Its vision is to build reusable, automated manufacturing satellites that can make drug ingredients in space and return them back to Earth to deliver to their customers without needing any astronauts on board.

With its first demonstration mission a success, Asparouhov said the company is ready to start making products for customers on its orbital manufacturing platform. These wouldn’t necessarily be small batches, either. As an example, Asparouhov said one of Varda’s craft could be optimized to make ingredients for around 200,000 doses of Keytruda in space at a time.

“I think Varda will be the first company to actually show that there’s value to atoms being moved back and forth from space,” he said.

This article was first published on forbes.com and all figures are in USD.