Fresh from a billion-dollar valuation, Advanced Navigation is shooting for the stars with a new plant to increase its production tenfold.

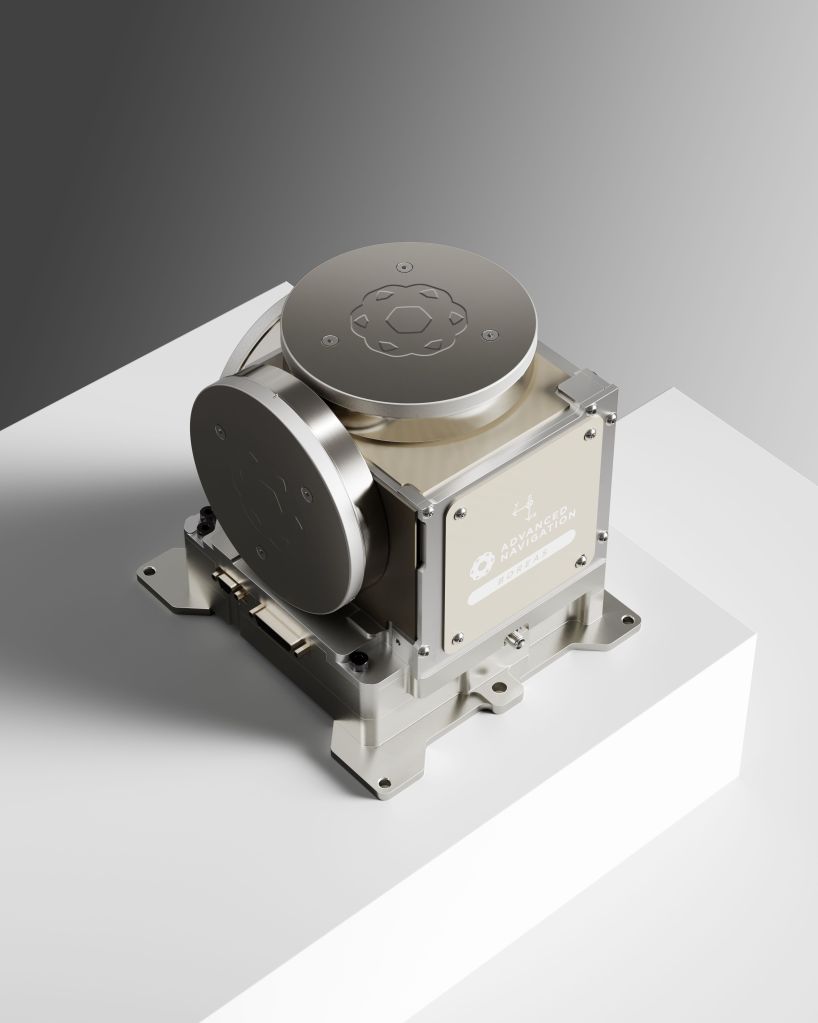

Advanced Navigation is guiding all the thousands of robotic Amazon trucks driving between warehouses in the US. Its technology steers satellites and will be guiding a lander to the moon in 2025. It is steering Swedish tanks and inspecting offshore windfarms. And the Australian billion-dollar start-up today announced a new factory which will increase its production up to tenfold and be one of only four facilities in the world capable of making fibre-optic gyroscopes.

“It adds a real sovereign capability to Australia,” says Advanced Navigation CEO and co-founder Xavier Orr. “It’s like a really accurate version of what’s in your phone. These are really challenging to produce. There’s only four companies in four countries that can produce them. It’s all strategic-grade and will be exported, primarily to the US and Europe.”

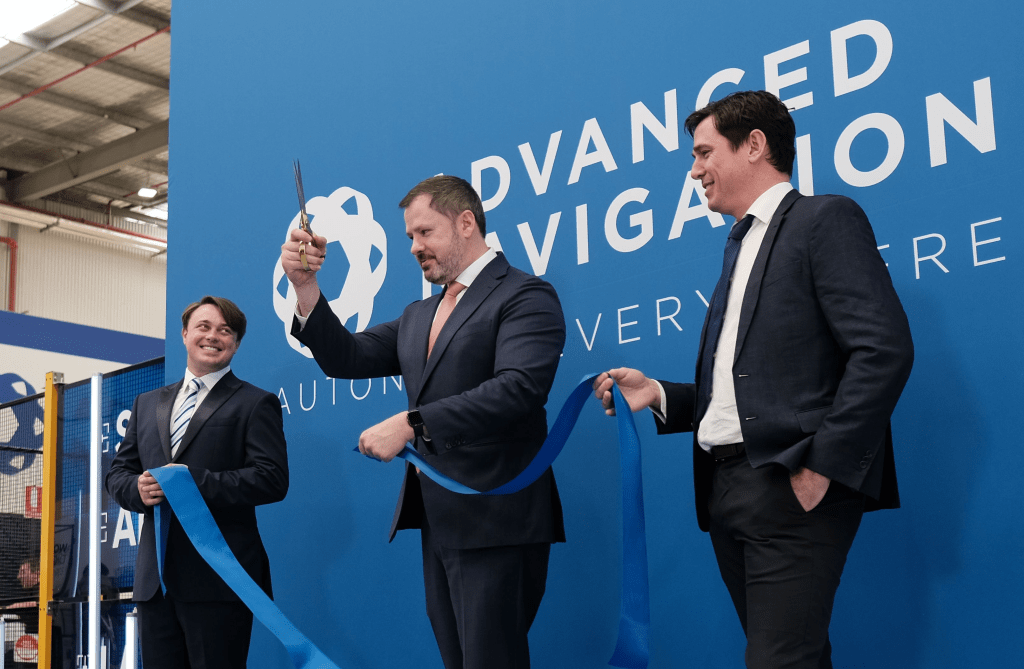

In opening the factory in the southern Sydney suburb of Botany yesterday, federal Industry and Science Minister Ed Husic likened Advanced Navigation’s achievement to the winged-keel design that powered Australia II’s America’s Cup victory in 1983. “You look at the way this company has been around for just over ten years and they defied the orthodoxy that had been in place for over 50 years and to challenge the notion that this is the way things have always been done.”

Former prime minister Malcolm Turnbull is a director. He told Forbes Australia that he first invested in the company in their 2019 funding round and reinvested last year. “Of the 20 venture positions that I hold this is one of my largest,” he said. He said his usual practice with startup investments was a minimum of US$500,000 and a maximum of US$2.5 million, usually at the Series A or B stage.

“I’ve long said that Australia’s future prosperity lies in innovation and like Ed (Husic) said, I put my money where my mouth is.”

Advanced Navigation was founded by two friends from University of West Australia, Xavier Orr and Chris Shaw, in 2012. Orr was an engineering undergraduate when a lecturer, Dr Adrian Keating, tipped him into focusing on a nascent field that was talking about creating an “artificial brain inside a computer”.

“What he was selling me was what has led to AI now, and is called neural networking,” says Orr.

In 2009, Orr’s final year thesis was on a neural network algorithm specialised for physics applications. “That algorithm thesis had really good results,” says Orr. “It had a ten-times performance improvement over the traditional stuff.”

“It’s a myth that Australia is slow and uncompetitive. I think companies used it as an excuse when they moved things offshore.”

Chris Shaw, co-founder Advanced Navigation

Around that time, he caught up with Shaw – who was doing electrical engineering – for lunch. They both had side jobs working for early drone companies, so navigation was on their minds. Orr told Shaw he had an idea for a company, Shaw recalls. “And I was like, ‘That’s interesting cause I’ve had the idea to start a company doing the same thing.’ So we almost both came up with the same idea at the same time. I was looking at it from the hardware perspective and Xavier was thinking the software.”

Shaw explains that Orr’s breakthrough was to treat the “noise” from all the signal inputs going into a navigational device and to use AI to smooth it out, in the same way AI can remove crackling noise from an old audio recording.

It enables systems to more accurately know where they are without the need for GPS signals.

The field of robotics and autonomous vehicles was just getting started and Orr says that from the very start he saw that his algorithm had uses across the full gamut of autonomous vehicles, from self-guided farm equipment to drones, boats and spacecraft.

He started a PhD, but dropped out early to start Advanced Navigation, realising that if he published, he’d be telling the world his secrets – and the university would own a chunk of the intellectual property. “So if you’re going to commercialise something, you want to not complete your PhD,” Orr advises. They took out personal loans, maxed their credit cards, and Shaw started building the navigational devices in his Subiaco garage.

They took their system on an international roadshow and made early sales. “We were profitable after nine months,” says Orr. They quickly paid off their debts.

“We get really good margins,” says Shaw. With still only the two of them, Shaw was assembling all the units himself. “We were very capital efficient early on. We were selling hundreds of units in the first year. And that was able to fund the growth initially.” They were still in the garage when Shaw built their first assembly robot to increase production.

“We grew quickly from there into our first commercial premises. Then moved quickly to headquarter in Sydney because a lot of our customers were global. It was a better environment to be based on the east coast. But we still have a big presence in Perth. Early this year we opened a 4000 sq m manufacturing facility in Perth and have an engineering team working on all our underwater technology there.”

Advanced Navigation employs about 250 people and has five engineering centres, all in Australia – in Canberra, Brisbane Newcastle Perth and Sydney. As well as sales teams in California and Europe with plans to open more in South Korea and Japan.

It has customers in more than 70 countries. Clients include Boeing, Tesla, Google, Apple, NASA, Airbus and General Motors.

The company raised early money through David Shein’s Our Innovation Fund. It raised $20 million in a 2019 Series A round, with the CSIRO-backed Main Sequence Ventures, and US funds Brick & Mortar and In-Q-Tel (linked to the CIA).

It did not need to raise again until late last year when it defied the tougher capital-raising conditions to bring renowned US private equity fund KKR onto the books as part of a $108-million Series B.

That raise was done at an estimated valuation of $1 billion. Orr did not dispute the number.

The company has been doubling both revenue and production annually, Orr said. They are currently shipping about 15,000 units a year and the new factory will give them the capacity to produce ten times that, with room further expansion.

Shaw said Australia was very competitive at the high end of manufacturing. “It’s a myth that Australia is slow and uncompetitive. I think companies used it as an excuse when they moved things offshore, maybe. There might have been other reasons, but if you invest in automation and have the right processes, Australia can be competitive on price. And our suppliers here are all cost competitive too.”

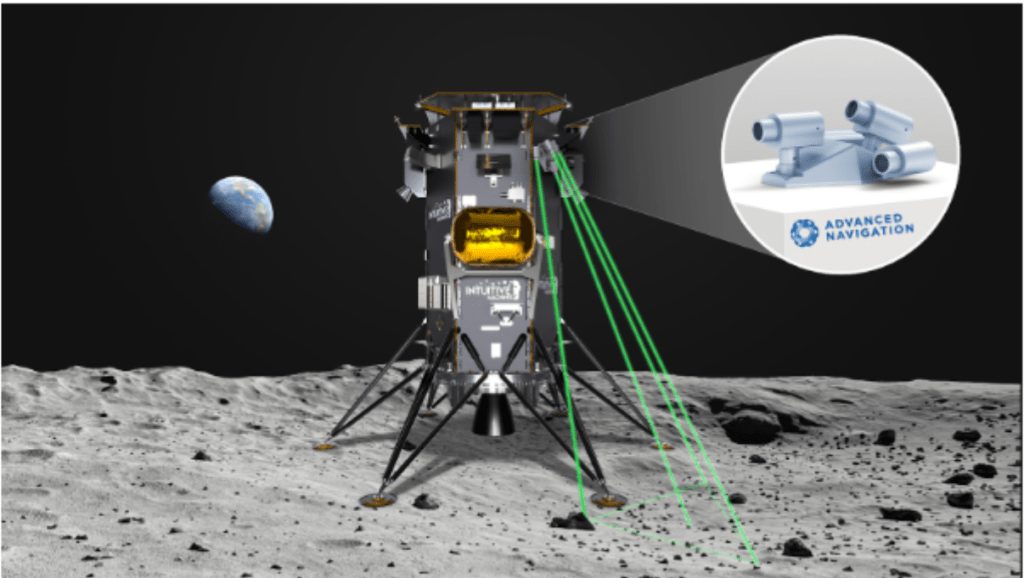

The company was awarded a $5.2 million Australian federal grant in June to accelerate its development of the technology that will help spacecraft land on the surface of the moon as part of NASA’s ongoing Commercial Lunar Payload Services (CLPS) program, guiding the US-based space company Intuitive Machines’ craft.

The LUNA (Laser Measurement Unit for Navigational Aid) will be used in the crucial area where recent Russian and Indian moon missions failed: bringing the craft in what can be swirling dusty conditions where cameras don’t work.