Paddy Neumann’s innovative satellite thruster will be launched into orbit in coming months. His company announced its first sale last week for a revolutionary scheme funded by the US Space Force to turn space junk into fuel. And he can trace the origin story back 65 million years.

Paddy Neumann got into space via dinosaurs. He still has a favourite, “because ankylosaurus is pretty badass”. He was about five when he first heard they’d been wiped out by an asteroid.

“I thought, ‘That’s cool. What’s an asteroid?’” he recalls. So young Neumann went to the library and found the books about space on the shelves below the palaeontology books he already knew so well.

It was 1989, and NASA’s Voyager II spacecraft was sending back messages from Neptune. “I remember some grown-ass nerds dancing around because the signal from Voyager dipped the way they predicted it would,” says Neumann. “‘These guys know how to have a good time,’ I thought. ‘Maybe this is something I could do.’”

Of course, Neumann wanted to go one-small-step further and be an astronaut, but soon realised he “was neither Soviet enough to be a cosmonaut nor American enough to be an astronaut”.

“The three Australian-born astronauts to that time had got there by being very good at science and/or engineering so I figured if I keep studying hard I might be able to do something like that. Maybe go on a shuttle mission, or visit (the space station) Mir.”

In a few months, Neumann looks set to achieve the next best thing. A thruster for propelling satellites and spacecraft through space that he dreamed up while a third-year university student in 2004 will be launched into space for its first trial run.

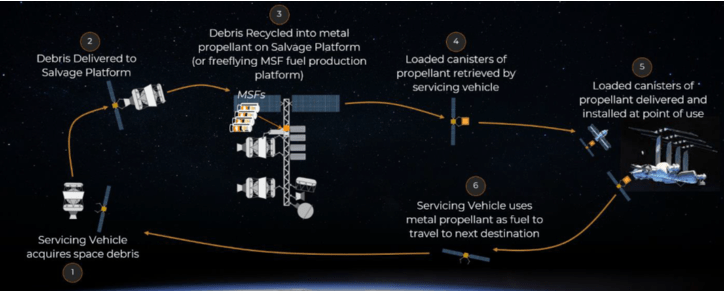

And the company announced its first sale, and first export, last Thursday, for the device’s incorporation into a US $1.7 million project led by CisLunar Industries which will see space junk recycled – in space – into the solid metal fuel used by the Neumann Thruster so that more space junk can then be collected.

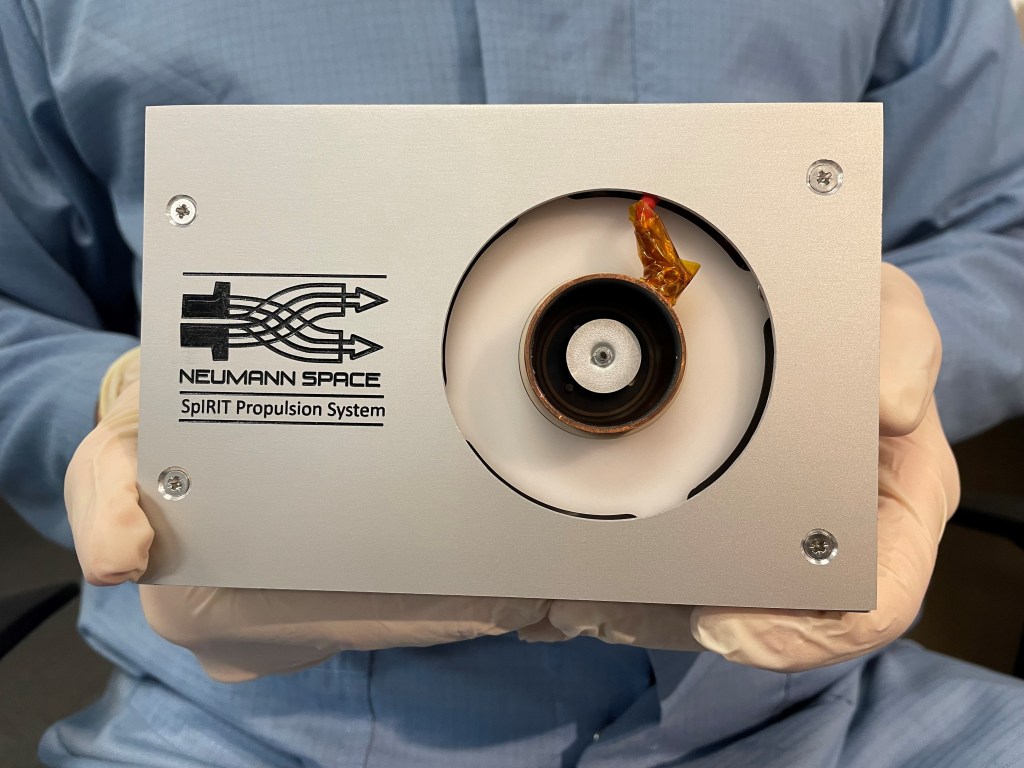

Neumann Space also announced last month that it had finished integrating its drive onto Canberra-based Skykraft’s Australian-designed and manufactured satellite (pictured at top) ready for launch around June.

Additionally, the Neumann thruster will be a key part of the SpIRIT spacecraft, the first selected for funding by the Australian Space Agency, which is due to launch later this year.

Neumann Space says it has “about seven” launches planned over the next 18 months, but most of them are covered by confidentiality agreements.

After Neumann’s lightbulb moment in 2004, he kept working on the idea through his honours, masters and PhD at Sydney University, until in 2015 he split the intellectual property off into his company, Neumann Space, where he is now chief scientist. The company employs 14 technical staff in Adelaide’s innovation hub – Lot Fourteen.

Neumann Space chairman Peter Schultz says they have met with all the major global space companies and remain in talks with them all with numerous memorandums of understanding signed. “Over the last four years we’ve gone from a couple of mad scientists messing around, to establishing ourselves as a well-run, well-organised space company at the cutting edge and we’re delivering some significant advances.”

Neumann Space’s prospects were given an enormous booster rocket in September last year when, in order to reduce space junk, the US Federal Communications Commission ordered that future satellites be required to re-enter the earth’s atmosphere within five years of decommissioning.

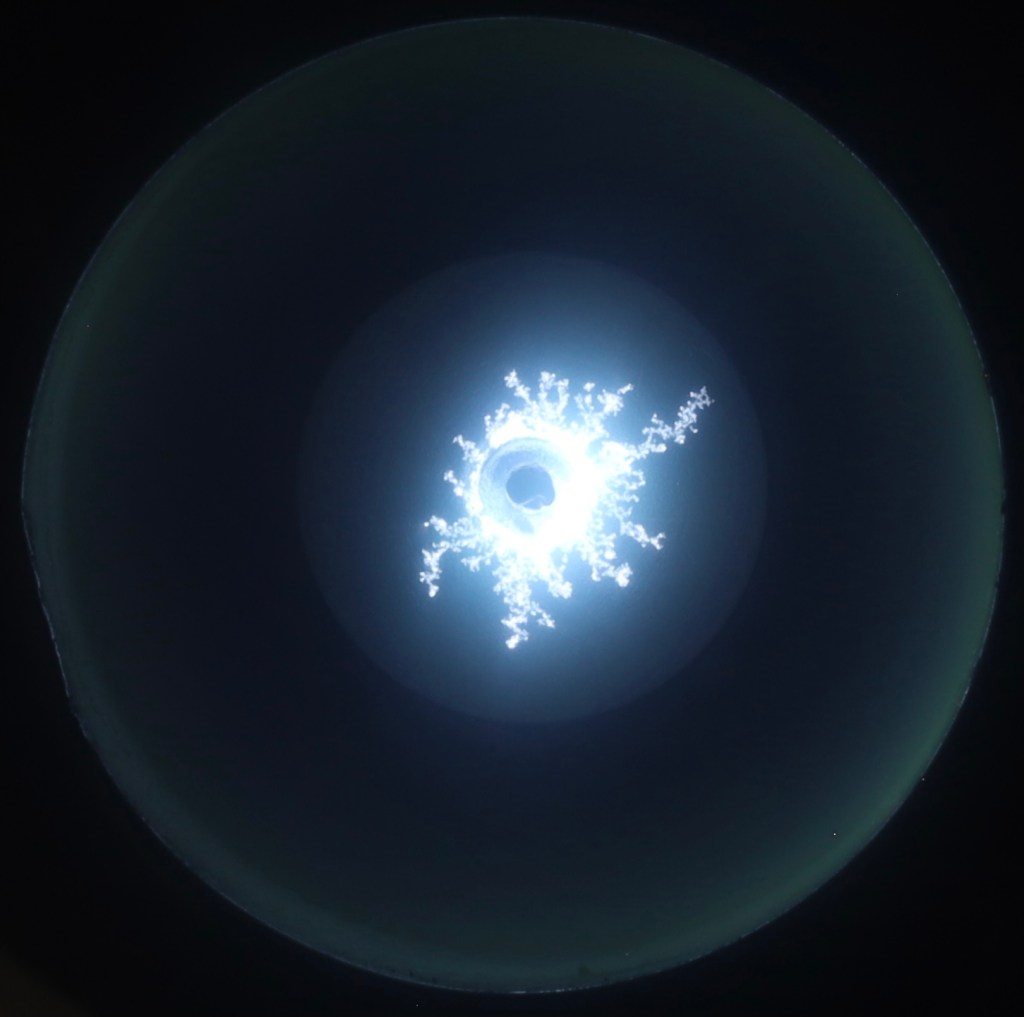

To achieve that, they will need propulsion systems, whereas 90% of current nano satellites have no such means of de-orbiting. And Neumann’s device – called a Neumann Drive – provides that with an extraordinarily simple idea that turns an ordinary cylinder of solid metal into gasses that create thrust as it expels those gasses out the back as exhaust.

The technology’s competitive edge is its solid-state, says Schultz. He tells the story of when he, Paddy Neumann and CEO Herve Astier met the chief technologist at NASA’s Jet Propulsion Laboratory, Dr Tom Cwik.

“We sat around the table with all their propulsion experts,” recalls Schultz. “‘Have you got anything to show us?’ they asked.”

Neumann opened his Pelican case, put on his anti-static gloves and pulled the Neumann Drive out of a plastic bag. They all admired the 10cm-long molybdenum cylinder attached to various boards.

“This is a nice model but what about the real thing?” one of them asked.

“No, this is a working product ready to bolt on,” Neumann said. “If you’ve got a satellite here, we could put it on. Actually, you can’t have this one, it’s spoken for.”

Schultz says it’s shelf stable. It goes in carry-on luggage when the travel. “A lot of people think it’s going to be glowing green,” he says.

“The questions that they’re asking have stopped being, ‘Does it work?’ ‘How do you know it works?’ And started becoming, ‘How many can you make a year?’ says Neumann. “But no one’s going to want to sign a contract for a large number of these before it goes to space.”

Schultz and Neumann decline to give financial figures for Neumann Space. “What numbers we can talk about is numbers of satellites that are due to be launched,” says Neumann. “The small satellites are exploding in popularity. SpaceX is launching several thousand per year.”

The US Federal Communications Commission received applications to launch 64,000 satellites over the last two years. Elon Musk’s SpaceX alone has said it wants to launch 40,000 satellites over the next decade. China has announced plans for a 13,000 strong constellation to counter SpaceX’s Starlink. “Then you’ve got Amazon, Facebook, Sony, Samsung, OneWeb and a whole lot of others launching small satellites that will require propulsion systems so that each is in the correct orbit and the correct spot in the orbit so they’re like a necklace rather than a clump in the constellation,” says Neumann.

Related

“The estimate on the worldwide propulsion budget for nano satellites (1kg-50kg) and small satellites (50-150kg) is $6.1 billion over the next ten years.”

The various models of the patented Neumann Drives will sell for between $140,000 and $500,000.

Neumann Space is majority owned by Peter Schultz’s son James Schultz, best known as co-founder and CEO of the carbon-markets business GreenCollar. “James asked me to have a look at (Neumann Space). He’s far too busy for the day-to-day stuff. ‘How about you come out of retirement Dad and help me?’”

Peter Schultz had been an engineer who’d spent much of his career working with the process of “vacuum deposition” whereby ions of a metal are sprayed onto another in a vacuum such as happens with the glass of iPhones.

Schultz says that Neumann’s genius was to realise that space, being a vacuum, could be used for the same process and the speed with which those ions were shot out would create propulsion.

“When I read the patent in 2018, it was quite a surprise that I understood it,” says Schultz.

“The competitors have liquids in high-pressurised vessels which create all sorts of complications. Our propulsion is a piece of molybdenum, 100mm long, 25mm in diameter with a hole up the middle with an electrode. A bit like a spark plug.”

In CisLunar’s extraordinary potential application of the technology, the Colorado-based company has already demonstrated that it can create fuel rods for the Neumann Drive with recycled space junk. It opens up the potential for CisLunar’s junk-chomping spacecraft to create their own propulsion fuel in space. “Think of it like a garbage truck that can refuel itself,” says Shultz.

CisLunar Industries’ CEO, Gary Calnan, said that as the industrial “in-space economy” accelerates and as the space domain becomes more contested, the The US Space Force – the US militaries space wing – had a need to be able “to manoeuvre without regret”.

“Our Modular Space Foundry and our partners’ capabilities allow us to turn space debris into

propellant for the Neumann Drive, which can then be used to retrieve more space debris, support

the Space Force SAML (Space Access, Mobility, and Logistics) mission, and provide materials for in-space manufacturing and construction. With the Space Force’s foresight to invest in our combined capabilities, what we are creating now lays the foundation for a full-scale industrial economy in space.”

Neumann is predicting a flood of orders once the early test flights give them “flight heritage” – the space industry’s term for “track record”.

“We’ll be doing the manufacturing under contract, but doing the assembly, the integration and the testing ourselves.” He anticipates a capital raising will be required to scale up once the flight heritage is established.

Nineteen years after first coming up with the idea, Neumann is getting frustrated with the multitude of systems checks required to get a satellite into space. “I’m like ‘Come oooooooon! I want to test my thruster.’”

Forbes Australia Issue Four is out now. Tap here to secure your copy and membership.