Food Recycle eyes $3 million capital raise – and international expansion

Founded by Norm Boyle in 2017, Food Recycle Ltd is an Australian start-up focused on turning commercial food waste into valuable animal feed. Seven years on, the company’s international division is planning global expansion – and seeking the capital to fuel it.

BRANDVOICE

Norm Boyle first clocked the food waste problem decades ago, when he was contracting on an orchard farm in Tumbarumba, NSW. But it wasn’t until 2017 that he and the team at Food Recycle Ltd (and later their international arm, Food Recycle International Ltd) developed and patented a solution to divert commercial food waste into valuable animal feed. After successful trials in Australia, conducted by two universities and the CSIRO, the company is planning international expansion – and on the hunt for licensees.

“We’ve flown under the radar to a certain extent,” Boyle explains. “We haven’t wanted to go out and say, ‘Hey, look what we can do’, without having scientific validation. Now, we’re ready for commercialisation.”

But food waste isn’t just about fallen farm fruit: it’s a significant global problem with industries like aged care, hospitality and manufacturing creating large volumes of food waste. According to statistics, in Australia alone, more than 30% of all food produced (that’s commercial and household) is wasted. And it’s estimated that our total food waste tops 31.2 million tonnes annually. Food Recycle, with its technology, will repurpose millions of tonnes of commercial food waste annually. Globally, 1.05 billion tonnes of food waste was generated in 2022, which equates to about one-fifth of all food available to consumers (according to UNEP).

The conversion process

But unlike other food waste conversion start-ups, Food Recycle says it’s landed on a truly unique, sustainable, scalable solution. It works by collecting food waste streams separately (i.e. nursing homes, restaurants, supermarkets, abattoirs). It then puts each food waste stream through a three-step process, which includes maceration and depackaging, dehydration and biosecurity. The result is a dry, granulated powder, with less than 10% moisture.

Following the biosecurity step, Food Recycle then uses a feed formulation program to determine how much of each of the food waste streams is needed to produce a complete animal feed, whether it be for poultry, pigs or aquaculture species. The combined food waste streams in varying percentages produces a tailored nutrient rich feed.

“And each day the nutrient profile of the food waste streams may change, so we will vary how much of each food waste stream we use to create each batch of complete feed,” Boyle says.

“We’ve taken away the variability of the food waste by having multiple food waste ingredients that are shelf-stable and biosecurity-safe that we can mix and blend depending on the animal’s needs.”

Norm Boyle

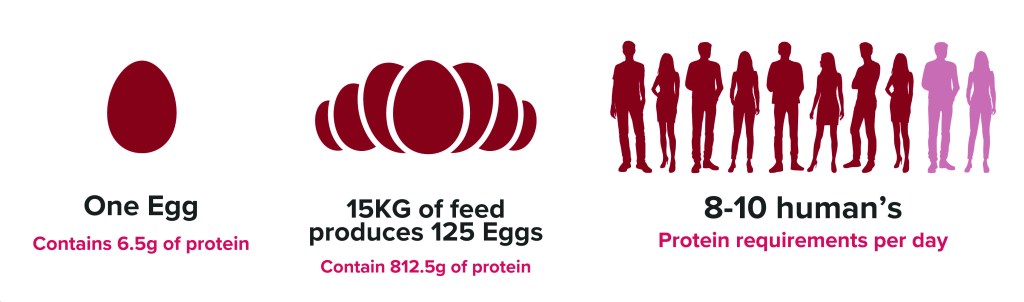

The circular economy effect of Food Recycles tech is that for every 30kg of food waste, Food Recycle can produce 15 kilograms of say poultry feed, which in turn produces 10kg of chicken, or 125 eggs.

“In a recent CSIRO Jade Perch aquaponics trial, we found that our process will produce 15 kilos of Jade Perch feed from 30 kilos of food waste. So, from the 15 kilos of Jade Perch feed we will be able to put back on the supermarket shelf 10 kilos of fish and 80 kilos of leafy greens,” Boyle says. “The amount of leafy greens astounded me.”

Feed trial validation

Food Recycle has since relocated its pilot facility from the University of New England to the Bega Valley where it processes food waste streams for animal feed trials and testing by Western Sydney University, the University of New England and the CSIRO. A 40-week study conducted at UNE’s cage-layer facility found hens offered food waste-based diets outperformed their controlled commercial feed counterparts, and there was no effect on egg production with food waste-based diets.

One of the CSIRO studies found that a 67% food waste-inclusion diet improved barramundi weight gain by 35%.

International expansion plans

With trials proving a success, Boyle says Food Recycle Ltd has expanded to the Pacific Islands, including Papua New Guinea, and its international arm, Food Recycle International Ltd, is set to take on the rest of world. Its patents extend to 120 countries, and don’t just cover the original technology – they also cover improvements to its processing technology.

“At great expense,” Boyle adds. “Our shareholders have committed millions in investment. It’s a long, hard road to building an evidence-based company – and commercialisation is no easier.”

So far, the company has identified some key markets overseas, including the Middle East, particularly Saudi Arabia and Qatar.

“These places are experiencing significant food security issues, and our food waste to animal feed technology significantly addresses sustainability, circular economy, environmental and food security outcomes,” Boyle says. “Saudi Arabia, for example, has to import 100% of its poultry feed, and they have a large poultry industry. So, if they can mitigate some of the risk of having to import traded commodities, which also vary in cost, it’s a good outcome for them.”

Food Recycle plans to expand via licensing agreements and is seeking licensees to set up production facilities across the globe. Each production facility costs about US$22.5 million (AU$32 million) to establish, the licensee makes milestone payments, which benefits both Food Recycle and the licensee. Food Recycle provides operational training, food waste resource support and R&D upgrades. The company doesn’t charge a licensing fee, however, the licensing agreement provides for a 4.5% royalty from the sale of feed produced.

Food Recycle Limited is also seeking $3 million in capital to fund its go-to-market strategy, Boyle says it’s already secured about $300,000 of that. Food Recycle International is seeking a separate $3 million for its international marketing campaign and international food waste resource programs.

For more information, head to https://www.foodrecycle.com/