Ian Wright, a Tesla cofounder who left the carmaker long before Elon Musk became CEO, wants to revolutionize different kinds of electric vehicles.

Ian Wright tests Dimaag’s battery-powered electric mower in Fremont, California.

Dimaag-AI

Instead of new battery-powered cars and SUVs, he’s working to create off-road work vehicles — think lawnmowers, ATVs and tractors — that don’t spew dirty exhaust and carbon dioxide. The first product is a commercial-grade electric mower that’s arriving just as California moves to ban sales of all new gas-powered mowers.

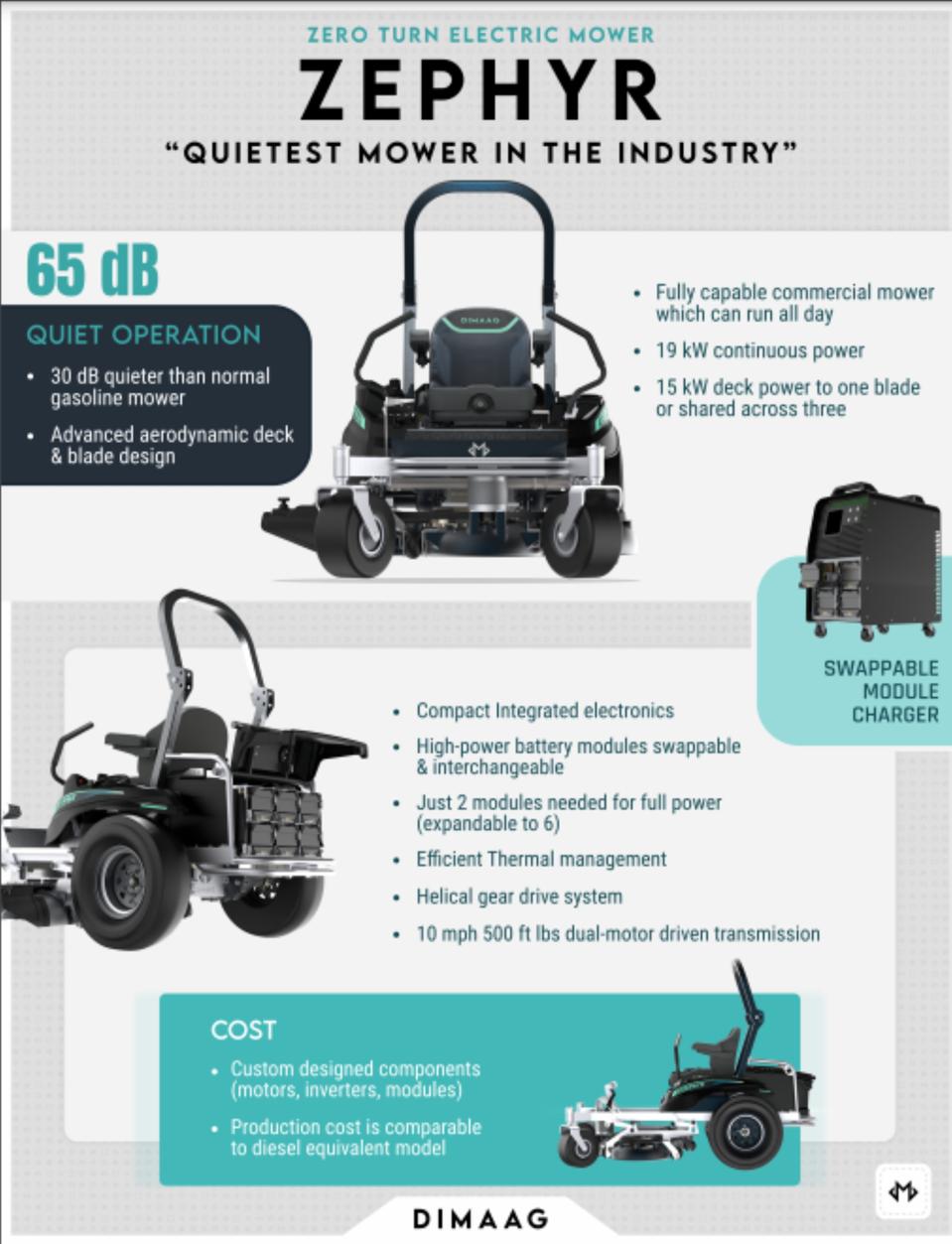

Wright is now the vice president of engineering at Dimaag-AI, a Fremont, California-based engineering firm designing EV and battery charging technology. The mower, called Zephyr, is powered by proprietary swappable lithium-iron battery modules.

Along with eliminating exhaust pollution, it’s low-vibration and so quiet users don’t need ear protection, Wright and Dimaag CEO Satish Padmanabhan told Forbes. Rather than producing it themselves, Dimaag is licensing its technology to a major maker of agricultural equipment Padmanabhan declined to identify.

The mower and Dimaag’s battery and charging system will debut at CES in Las Vegas next week, along with an excavator developed with Hitachi and a prototype all-terrain vehicle using the same swappable battery system.

“What we’ve been trying to do in the development of the mower in particular, not just the (battery) ecosystem and the other things we’re doing, is to make something we think the customers will go for like a pack of rats,” said New Zealand-native Wright. “It’s so much quieter and so much more pleasant to use and doesn’t have any of those nasty shortcomings — and doesn’t catch fire,” thanks to its lithium-iron battery chemistry.

While it sounds like a quirky niche, the mower arrives as California, which rivals the U.S. government in its ability to regulate vehicle and product pollution, outlawed the sale of new gasoline-powered landscaping equipment starting on Jan. 1, 2024, the first state in the nation to do so. Landscapers can continue using conventional mowers and leaf blowers they own, but eventually, thousands of dirty devices will need to be replaced. Gasoline-powered mowers run from $10,000 to $20,000 for commercial units, and electric models cost even more. So California is offering up to $12,500 rebates for qualified electric units to ease the price disparity.

“It’s so much quieter and so much more pleasant to use and doesn’t have any of those nasty shortcomings — and doesn’t catch fire”

There are already battery-powered units from other makers, including Toro, Gravely and Greenworks Tools, but it’s a very young market. And while it may seem like a small one, lawn and garden equipment are vastly dirtier on a per-gallon basis of fuel because they lack the exhaust emissions devices that have been standard on cars and trucks for decades. The California Air Resources Board estimates they were the state’s second-biggest source of air pollution in 2023, spewing more than 98 tons of exhaust per day, trailing only cars, pickup trucks and motorcycles, which blasted out about 168 tons every day last year.

Globally, gas- and diesel-powered commercial mower sales top 600,000 units a year, said Padmanabhan. Pricing for a mower using Dimaag technology will be set by the companies that ultimately make them, he and Wright said.

Unlike existing electric mowers already sold in California, Dimaag’s electric powertrain and battery system were tailored to how mowers and other off-road vehicles are used. Conventional lithium-ion cells, like those in Teslas, use cathodes made from nickel, manganese and cobalt (known as LMC), and are highly energy dense, making them ideal for rapid acceleration. But they can also overheat under some circumstances, triggering battery pack fires in the worst cases. By comparison, lithium-iron phosphate, or LFP, cells like the ones Dimaag uses are high power and medium energy per kilogram, making them well-suited to uses where speed isn’t required. Generally, they also don’t degrade as fast from frequent recharging and have less risk of “thermal runaways,” leading to battery pack fires. That makes them ideal for the low-speed work vehicles Dimaag is developing.

Dimaag-AI

The Zephyr mower needs a minimum of two small battery modules, each providing 10 kilowatts of power, to operate and can hold up to six. “They’re 50-volt modules, which keeps you under the high-voltage safety standard,” Wright said, claiming there’s “no electrocution risk.” When drained, they’re designed to be quickly swapped out and replaced with freshly charged modules from a rapid-charging system Dimaag designed, allowing continuous operation throughout the day.

Wright, along with Martin Eberhard and Marc Tarpenning, worked on the original concept for Tesla in 2004 and says he helped convince Musk to fund it. He left in 2005 — long before the company’s 2010 IPO (thus retaining no consequential holdings in it) — to start Wrightspeed, which designed an electric race car, the Wrightspeed X1, and later created electric powertrains for heavy commercial vehicles. He’s also worked on a project to develop a high-powered drilling system that bores through solid rock to make it cheaper for utility companies to bury power lines in remote, fire-prone parts of California.

CEO Padmanabhan, who cofounded Dimaag in 2018, said the firm initially raised about $2 million that year but has sought no additional outside funding. It makes money by completing specialized engineering and design projects for other companies, though he declined to identify any clients. The goal is to develop technology with IP value, which they retain, that can be licensed, as with its mower and battery, electric powertrain and charger system. Wright was initially an adviser and came on board full-time as vice president of engineering last year, the same title he had at Tesla.

“The mower is not the only thing we have done; we’ve done multiple vehicles, but it’s the first vehicle we are showing,” said Padmanabhan. “During our journey, we have found out which are the vehicles in categories where electrification makes sense. Can we create a better vehicle than the equal in diesel and gasoline?”

Wright sees an opportunity to electrify “a ton of” work vehicles and equipment that use 25-horsepower or smaller gasoline or diesel engines. “Anywhere you would find little Kawasaki V-twins or little 3-cylinder Kubota diesel engines,” he said. “We built an ecosystem that will work in that whole space, with proper batteries and proper thermal management, proper power levels and fast charging.”

This post originally appeared on Forbes.com